Advanced data analysis uncovering root causes and improving reliability

Advanced data analysis for equipment reliability

Thickeners are a critical component in many mining operations, but they are often plagued by instability, breakdowns, and inefficiency. This case study highlights how CFT applied advanced data analysis to uncover the root causes of variability and significantly improve thickener reliability.

The mining operation was experiencing:

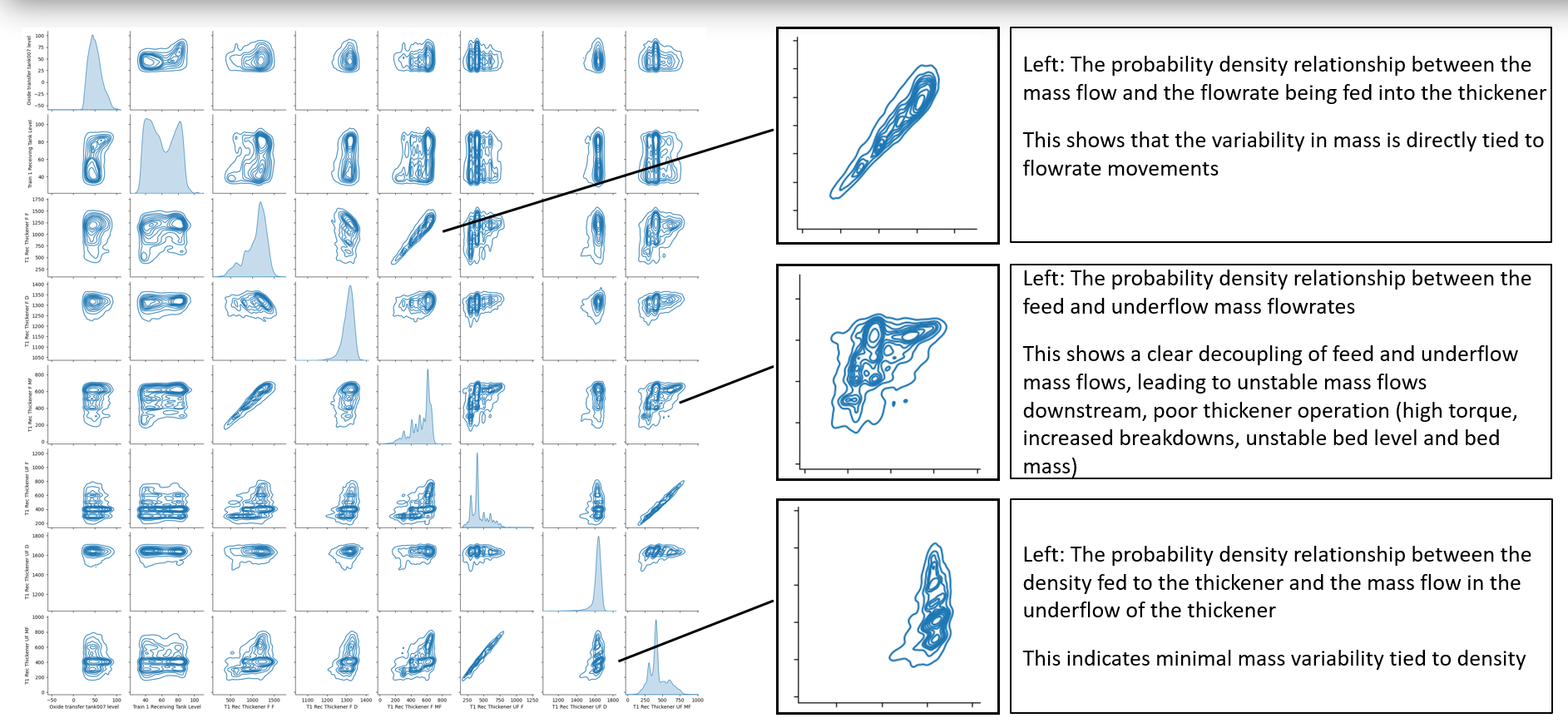

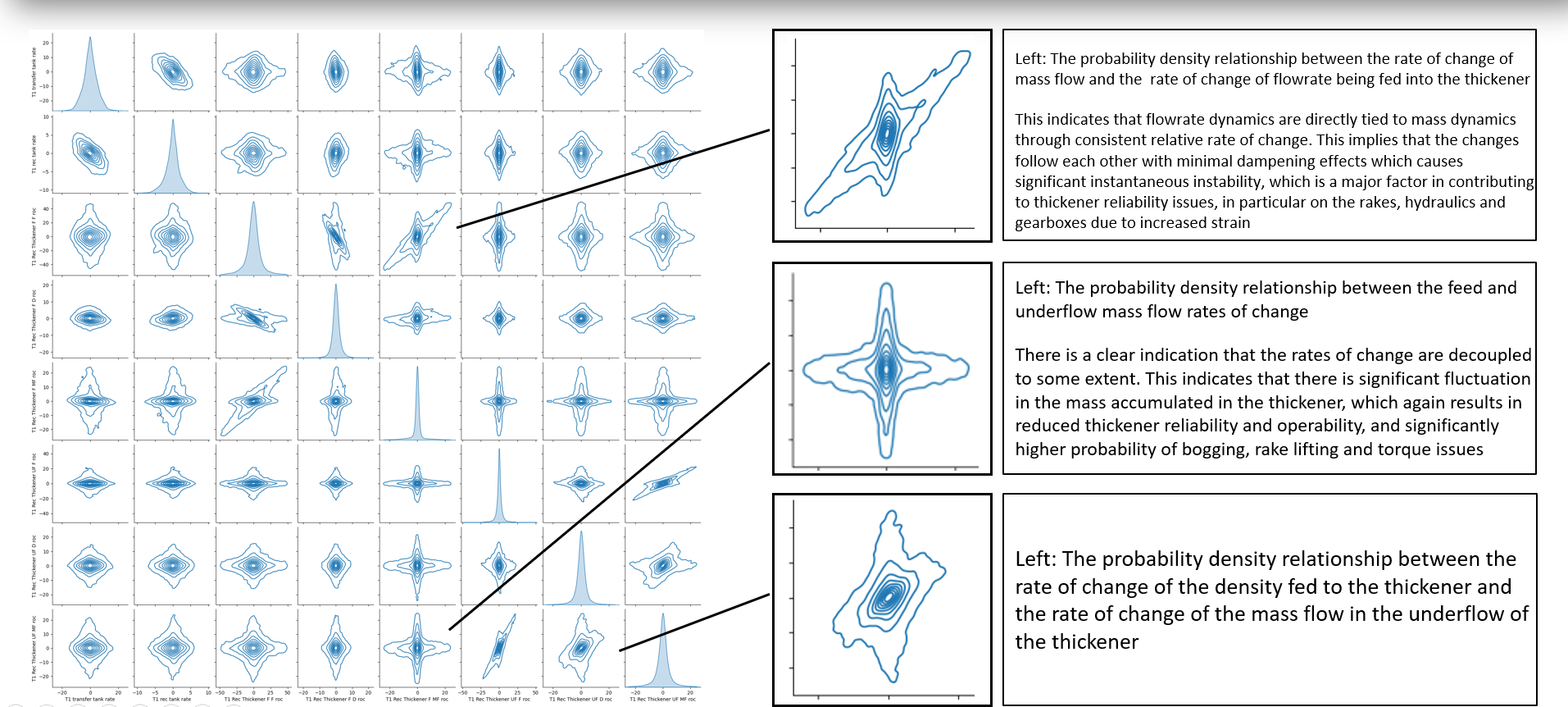

Through advanced statistical modeling, CFT identified clear patterns:

Instability was traced to fluctuations in the feed flowrate.

The feed and underflow mass flows were operating independently, causing inconsistencies.

Suboptimal dosing was contributing to poor clarity and increased breakdowns.

Probability density analysis revealing critical relationships between mass flow, flowrate, and density parameters

Detailed analysis showing how flowrate dynamics directly impact mass dynamics and contribute to thickener instability

6 Thickener Configuration Analysis

7 Thickener Configuration Analysis

Comparative analysis showing how optimization reduced the number of thickeners required while maintaining efficiency

More equipment doesn't always mean more efficiency. By deeply understanding thickener dynamics, we uncovered a path to greater stability with fewer machines.