AI-driven process control delivering 14% grade increase and 7% recovery improvement

Stabilizing operations and improving recovery rates

In the world of platinum group metal (PGM) mining, even small inefficiencies can have a massive impact on profitability. This case study explores how a PGM concentrator plant leveraged CFT's advanced analytics and AI-driven optimization to stabilize operations, improve product quality, and increase recovery rates.

The client's concentrator plant faced two critical constraints:

The plant sold its product to a smelter, which imposed significant financial penalties for deviations in product quality, specifically measured by:

A portion of valuable PGM material was consistently being lost during processing, reducing overall yield and profitability.

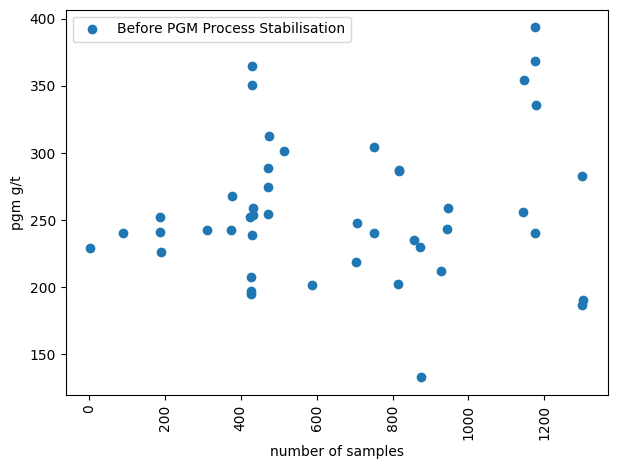

Our analysis revealed significant process instability that was impacting both product quality and recovery rates:

High variability and instability in process parameters

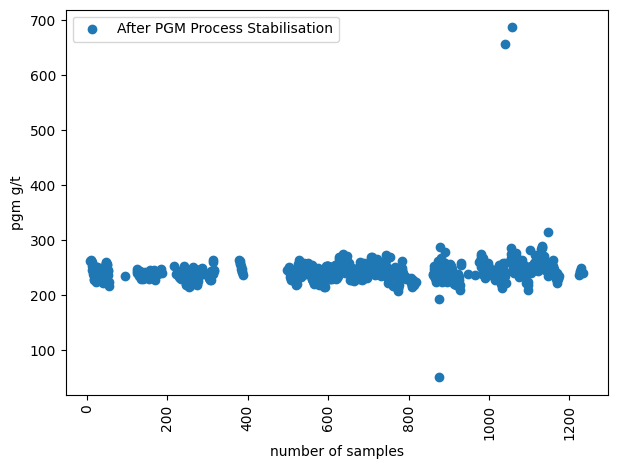

Stable, controlled process with consistent performance

The transformation from chaotic, unpredictable operations to stable, optimized performance was achieved through our comprehensive AI-driven approach.

CFT conducted a deep dive into the plant's historical data, process flow diagrams (PFDs), and equipment specifications.

Machine learning models were integrated with first-principle metallurgical models to uncover root causes of plant instability.

A custom solution was deployed to continuously provide optimal operational setpoint recommendations.

Operators could now simulate process changes before implementation, minimizing risk while ensuring stability.

The transformation was immediate and measurable:

By combining machine learning with metallurgical expertise, CFT enabled the plant to run in a highly optimized state, turning complex operations into a continuous cycle of improvement.